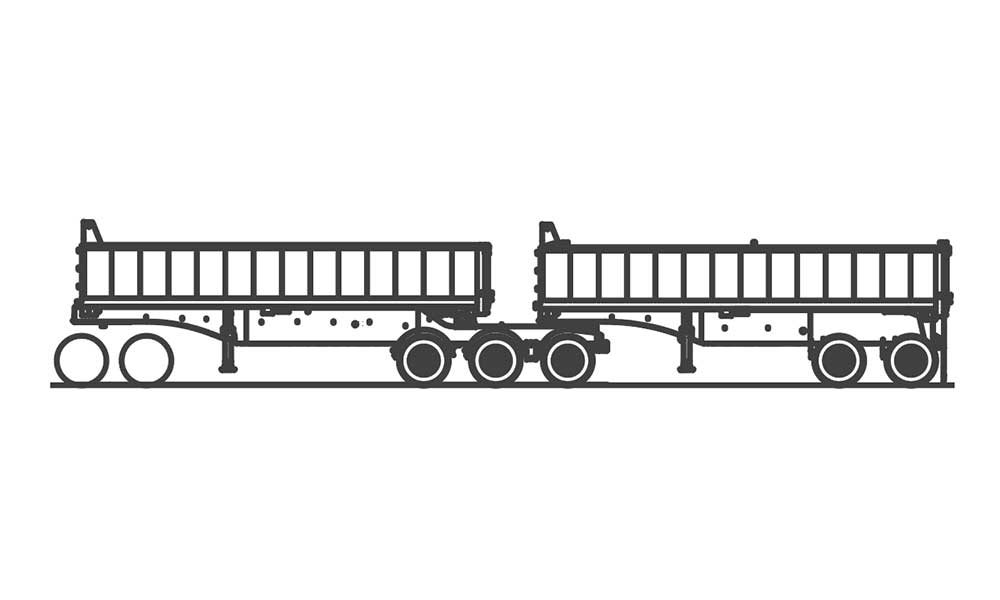

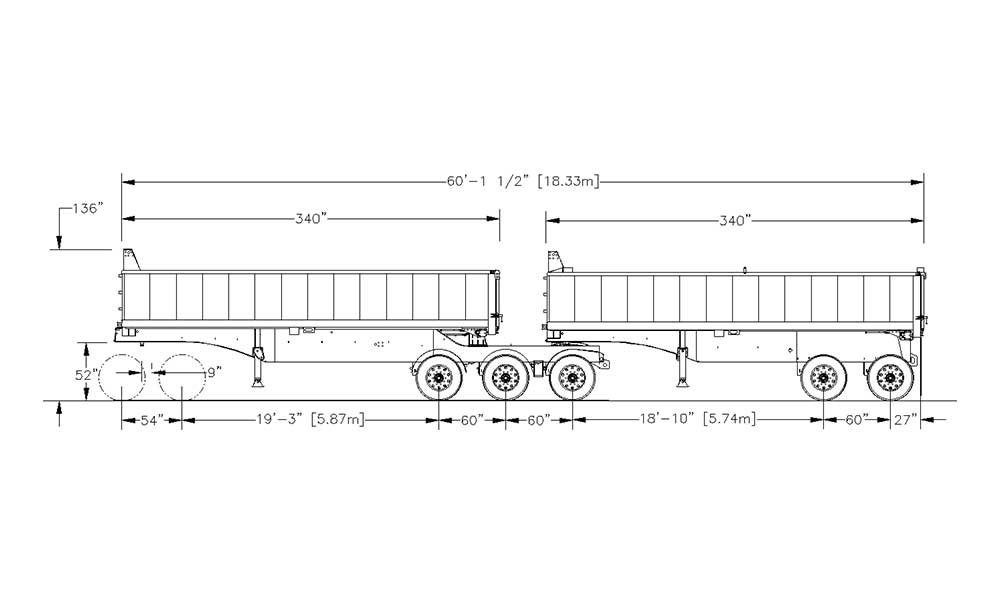

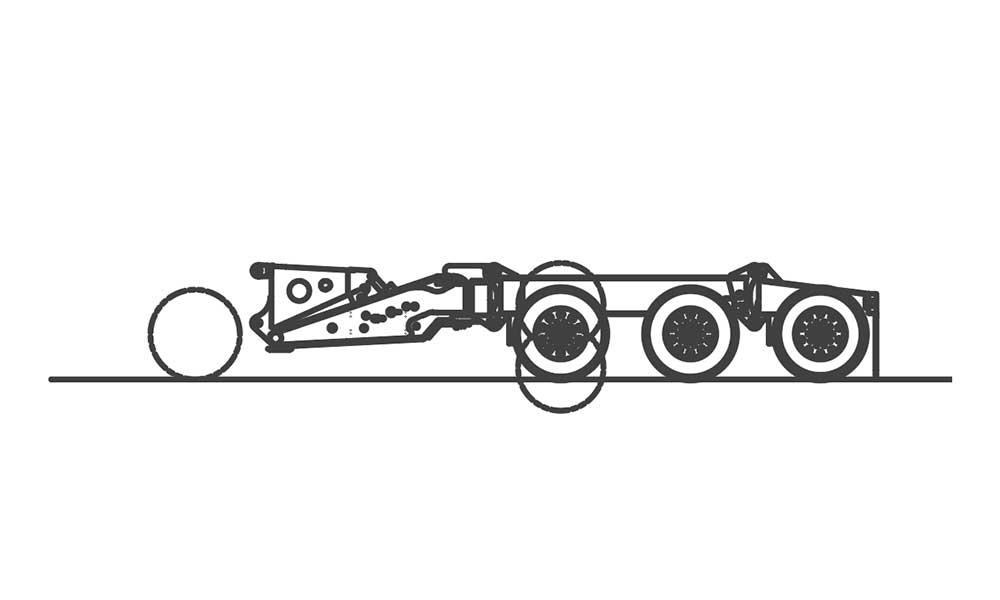

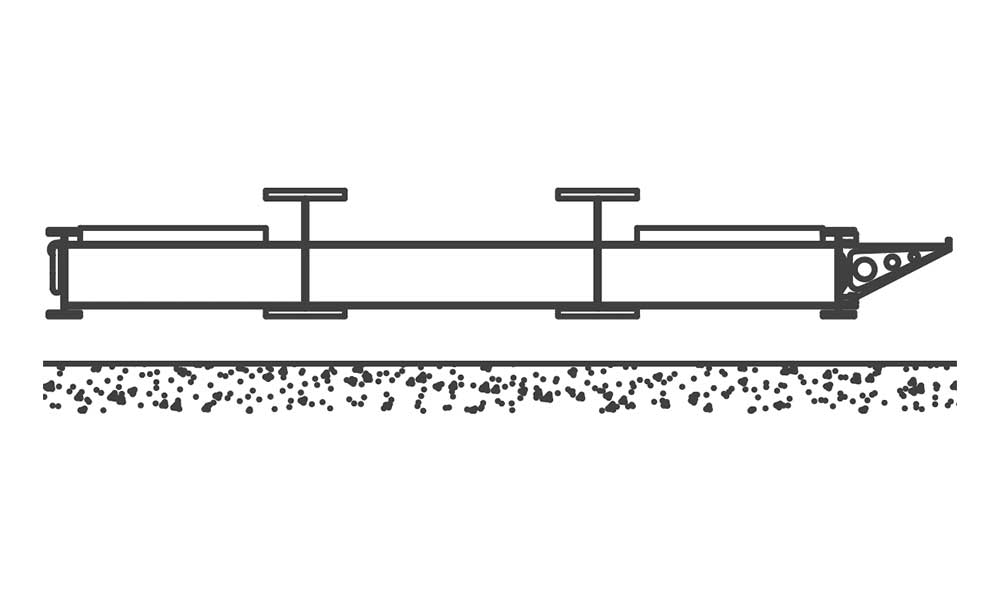

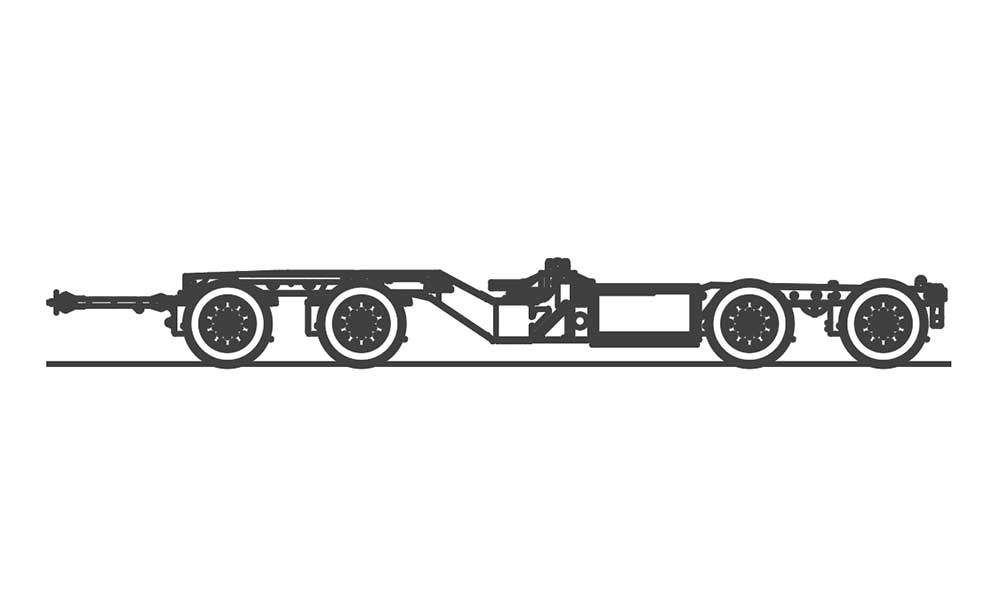

End dump refers to how the trailer is emptied. The large, multi-stage cylinder at the font of the trailers is used to lift the front of the box until the material slides out the rear. The B-train configuration capitalizes on the highest GVWR permissible on Canadian highways. Additional axles can be added to the configuration to conform to some US axle laws.

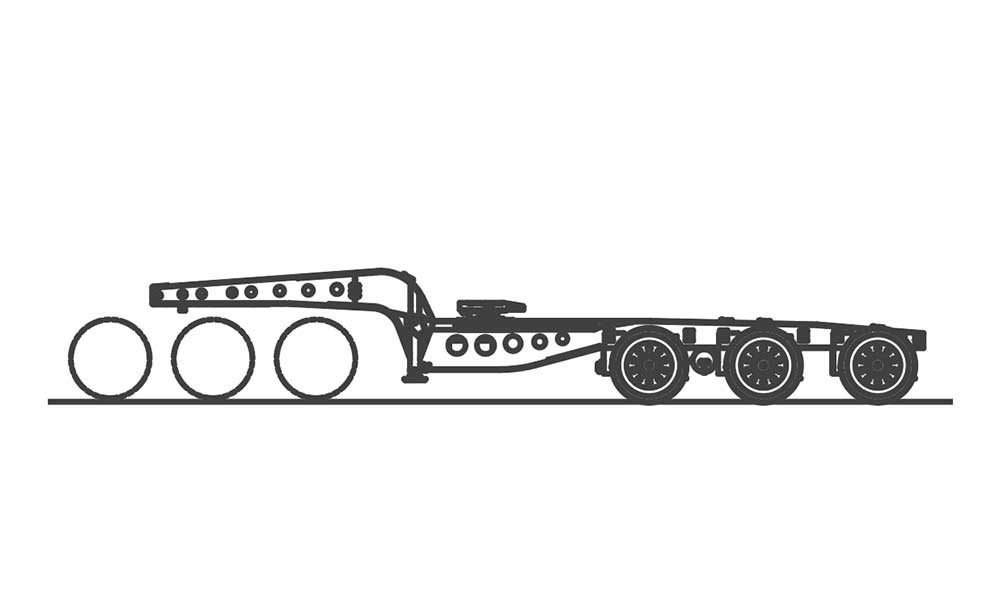

The rear trailer operation is the same as a regular end dump. The lead trailer needs to be un-coupled and have its box moved backwards to dump the load. The box is pushed backwards by an additional secondary hydraulic circuit. Once the box has been tipped, it is then pulled back in the forward position by the secondary circuit. The lead is then re-coupled with the rear to restart the cycle.

Tipping the box high enough to empty the load raises the center of gravity quite high. This unstable situation can reach a critical point on slanted or unstable ground that can ultimately cause the trailer to fall over. The relatively short boxes on the B-train configuration reduces the risk of a tip over.

The advantages of end dumps are that they are very simple both hydraulically and mechanically. This simplicity directly translates to lower maintenance and capital cost vs a live bottom or scrolling belt trailer. The other advantage of the end dump is that it can be used in a B-train configuration. The intermediate axle group and fifth wheel would make it impossible to house a live bottom or scrolling belt trailer mechanism.